Powder spreader

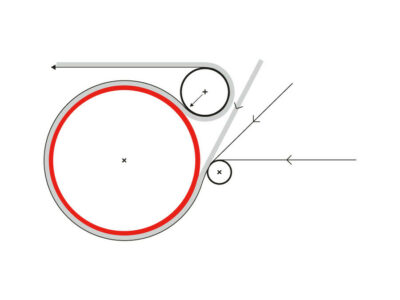

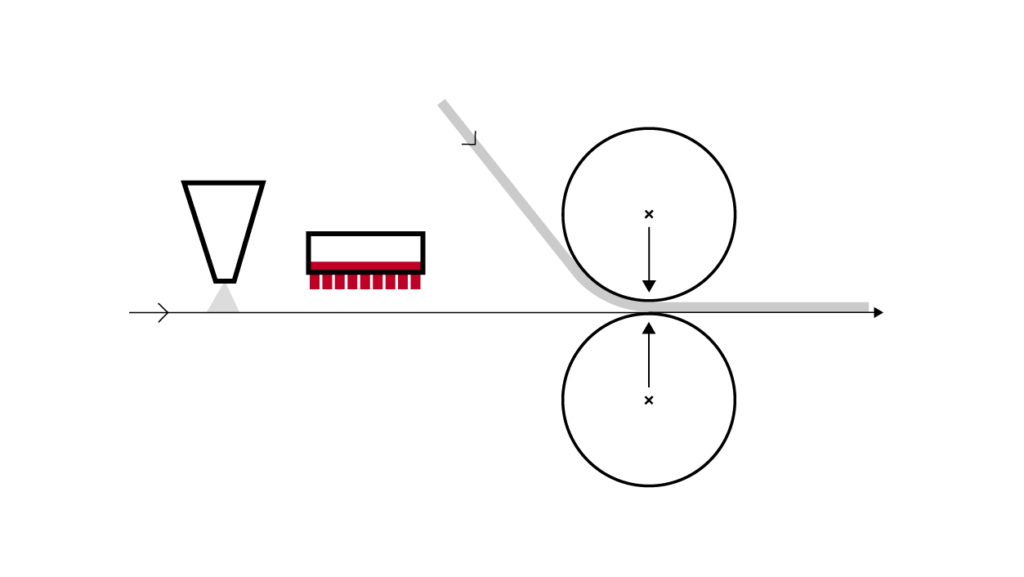

During treatment with a powder spreader, a powdered thermoplastic adhesive is spread evenly onto a substrate. This carrier with the powder adhesive then passes through an infrared heating unit in the next step, causing the powder to start melting and take on liquid form. A second layer can then be adhered to the first substrate, and pressure and cooling rollers will bond these two layers together.

This allows us to glue felt or non-wovens to the underside of carpets to give them more volume and a more comfortable feel. We can also laminate other assorted materials together in this way.

For some projects, we only apply the adhesive layer to the carrier, and, in his own production process, our customer will activate this adhesive again with heat to then adhere something to it himself. This machine has a maximum working width of 3 m 10 cm.

Other coating solutions

Ready to discover the right solution for your product?