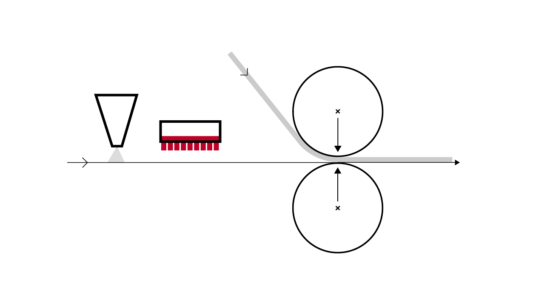

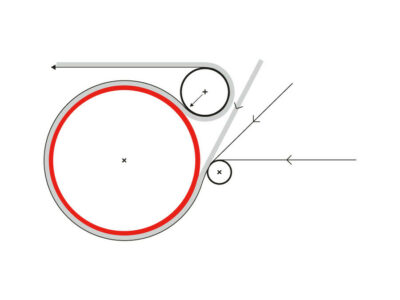

Multi-roller/gravure-roller laminator

This technique begins with an adhesive in solid form. This adhesive is heated using a heating or melting unit, making it liquid. The adhesive is then applied in liquid form directly to the material (such as woven materials, knits, non-wovens, foams, membranes, films, nets, etc.).

The adhesive can be applied in a continuous line or in spots. In this last case, the amount of adhesive can be kept to a minimum. It is a fully controllable process, in which the adhesive can be distributed very evenly across the substrate. The substrate itself is not heated, so it retains its properties and does not change its physical characteristics (stiffness, thickness, etc.).

The adhesives used ensure an extremely high bond strength in all materials that are exposed to very high loads in daily use. These can be either thermoplastic or thermosetting adhesives. They are therefore characterised by extremely high thermal resistance. This technique is also perfect for breathable application on textiles or other membranes, for example breathable textiles in the sports world. In collaboration with our customers and adhesive manufacturers, we are able to offer many solutions in different sectors. This machine has a maximum working width of 2 m 60 cm.

Other coating solutions

Ready to discover the right solution for your product?