Coating with squeegee

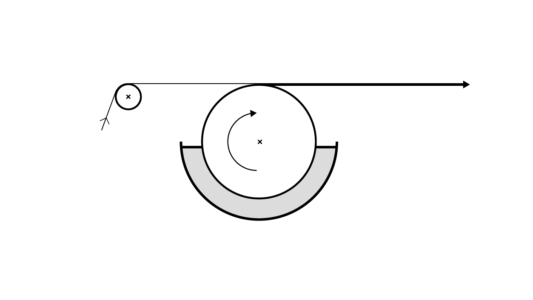

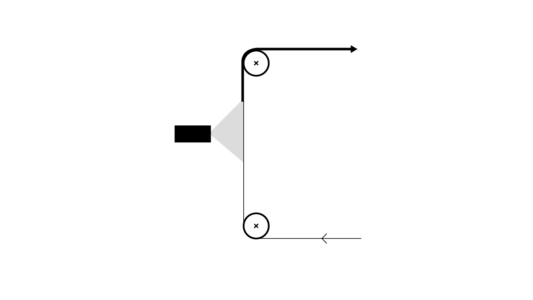

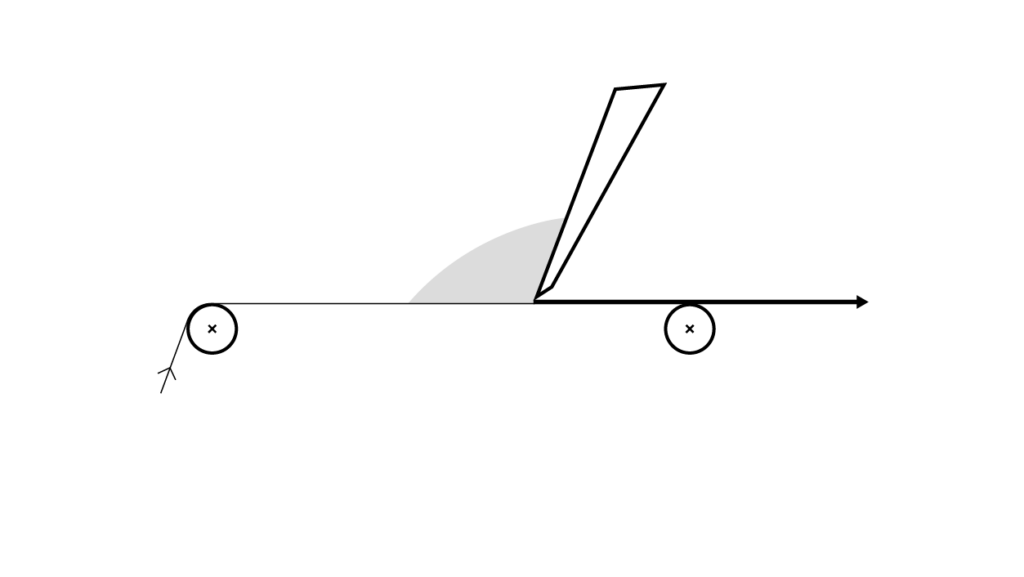

In this form of coating, also called knife coating, the fabric runs over a fixed blade (the squeegee or ‘doctor blade’), applying viscous pastes or foamed coatings to fabrics and substrates, in weights of 10 to 250 g/m2. The deeper the squeegee is pressed into the fabric, the thinner the coating.

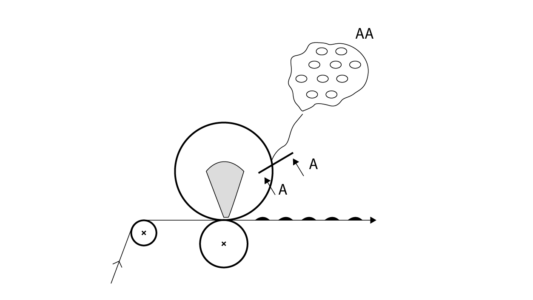

Coating with squeegee is ideal for waterproof top coatings for outdoor use, to improve the shear resistance of textiles, to apply water-repellent foam coatings or to make upholstery fabrics fire-retardant. The maximum width is 3 m 10 cm on a stretcher dryer.

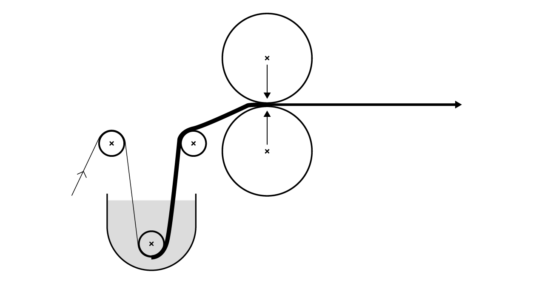

In the case of a ‘knife over table’ or split squeegee, the fabric is supported by a table and the coating runs through a gap between blade and fabric. The gap opening determines the thickness of the coating. This method allows weights of 20 to 500 g/m2 and thicknesses of 1 to 15 mm.

Coating with squeegee is ideal for applying a stable foam to wall coverings, making them more insulating and fire-retardant, or as a pre-preg in automotive finishing, etc.

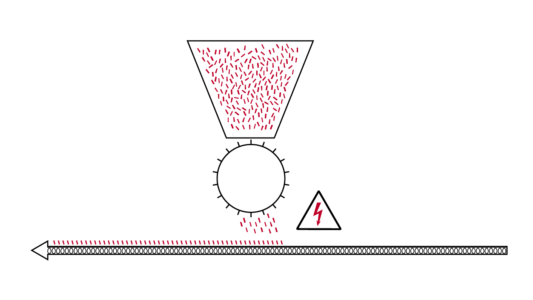

Other coating solutions

Ready to discover the right solution for your product?