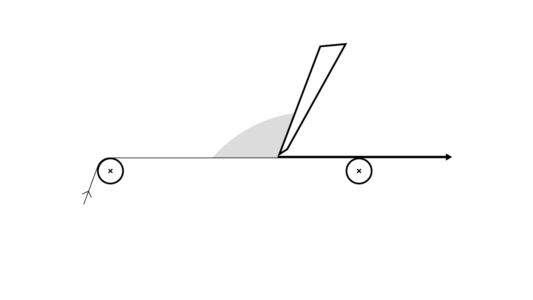

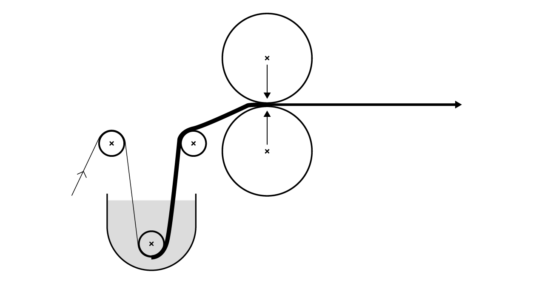

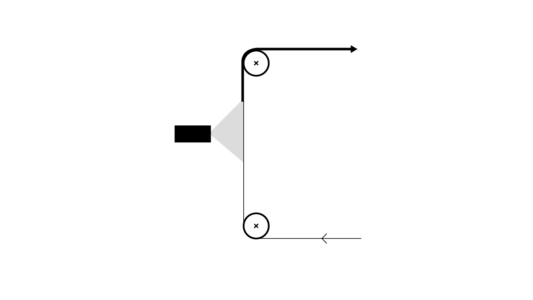

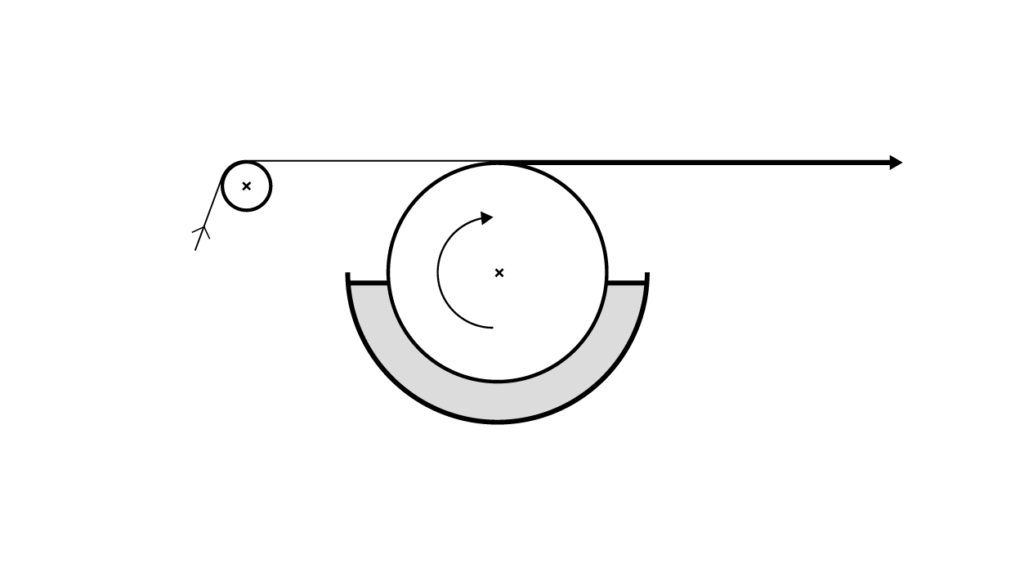

Coating with lick roller

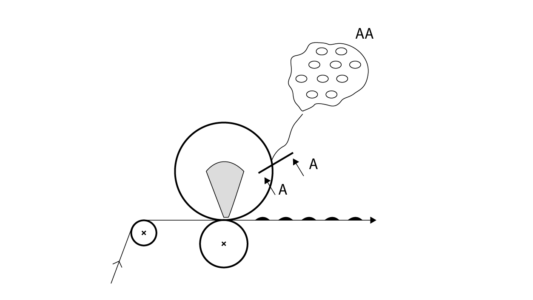

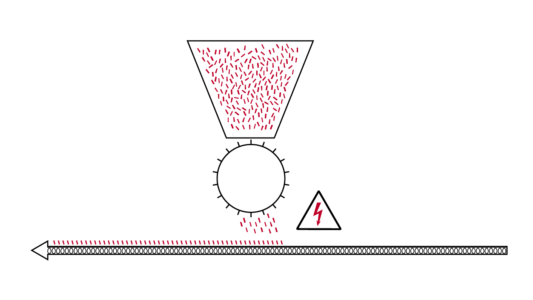

In this process, a chrome-plated roller rotates in a liquid or foamed compound, which is transferred onto the substrate. At the exit of the lick roller, the excess coating is scraped off by a blade. The final coating weight is determined by the speed of the lick roller, the mutual contact pressure, the viscosity of the coating and the position of the squeegee.

This technique allows liquid or foamed coatings to be applied to a wide range of substrates with a possible coating weight of 20 to 800 g/m².

Lick roller coatings are used to provide carpets with a pre-coat or anti-slip coating, to make furniture fabrics fire-retardant, or to harden filter materials. They are also particularly suitable for use in agriculture and animal husbandry. Lick roller coating can be carried out up to a width of 4 m 10 cm on a dryer without stretcher and up to 3 m 10 cm on a stretcher dryer.

Other coating solutions

Ready to discover the right solution for your product?