Coating with template

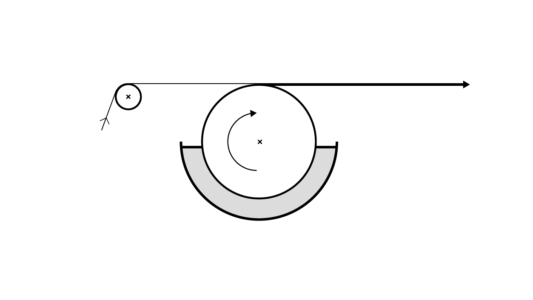

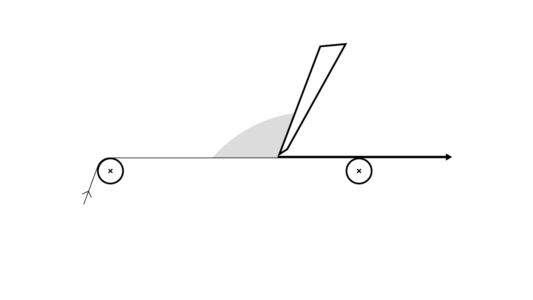

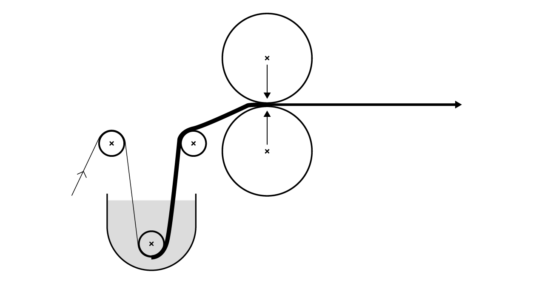

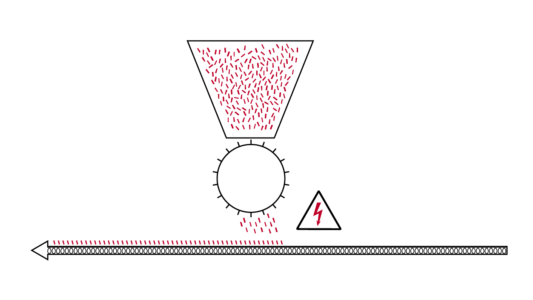

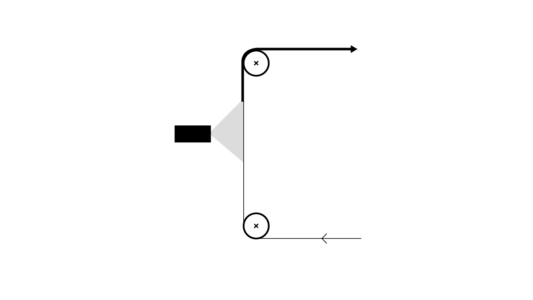

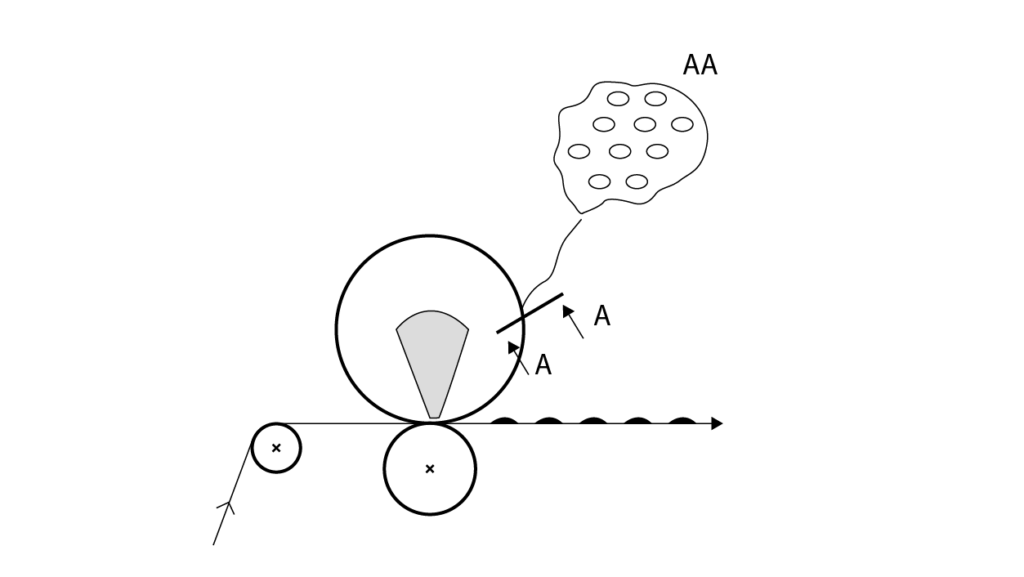

In template or screen coating, binders are pumped through a rotating screen in paste form or foamed up via a squeegee blade (open or closed system). The weight of the applied coating is determined by the openings in the screen.

This technique allows us to finish impact-sensitive substrates and coat a design. Additional extras: fabrics or substrates can be made softer, water-repellent, fire-retardant, anti-bacterial or anti-slip. Microcapsules can also be applied in this way. This treatment can be applied in all industries and to a wide range of substrates, with a maximum width of 2 m 40 cm on a stretcher dryer

Other coating solutions

Ready to discover the right solution for your product?